Our Business

We design and develop equipment that automatically inputs and discharges materials and parts with special shapes to general-purpose manufacturing equipment. Since the work that the workers have done so far can be performed automatically, it contributes to cost reduction, labor-saving, safety improvement, and cycle time reduction. The following devices are mainly available.

Injection Molding Machine

An injection molding machine is a device that processes synthetic resins such as plastics. Pressure is applied to the resin softened at high temperature, pushed into the mold, filled in the mold, and molded. We eliminate the waste of raw materials by accurately weighing and inputting the raw materials.

Machining Center

A machining center is an NC milling machine that has an automatic tool changer. A large number of cutting tools are stored in the tool magazine, and the machine automatically replaces the tools according to the commands of computer numerical control (CNC), resulting in milling, drilling, screwing, etc. and the processing can be performed continuously.

NC Lathe

NC lathes are equipped with numerical control devices on various lathes so that the moving distance and feed rate of the tool post can be indicated numerically. Currently, computer-based control (CNC) is the mainstream, and there is also a machine tool called a “turning center” that enables the drilling and milling of holes off the center of rotation. Normally, a turret-type tool post is provided, but many small NC lathes are provided with a comb-blade-type tool post.

Leak Tester

The leak tester is a test device for checking leaks in vacuum equipment. Leakage in a vacuum refers to the unexpected inflow of gas from the outside due to a minute hole in the vacuum chamber or a defective seal. Since the leak tester detects minute holes, it is also applied to search for leaks in pressure vessels and welds.

Washing Machine

There are many types of washing machines. Cleaning by spraying liquid at high pressure, cleaning by vibration such as ultrasonic waves, removal of impurities by heating, etc. can be mentioned. At our company, we design and develop a device that safely puts in and discharges the object to be cleaned into such a cleaning device without human intervention.

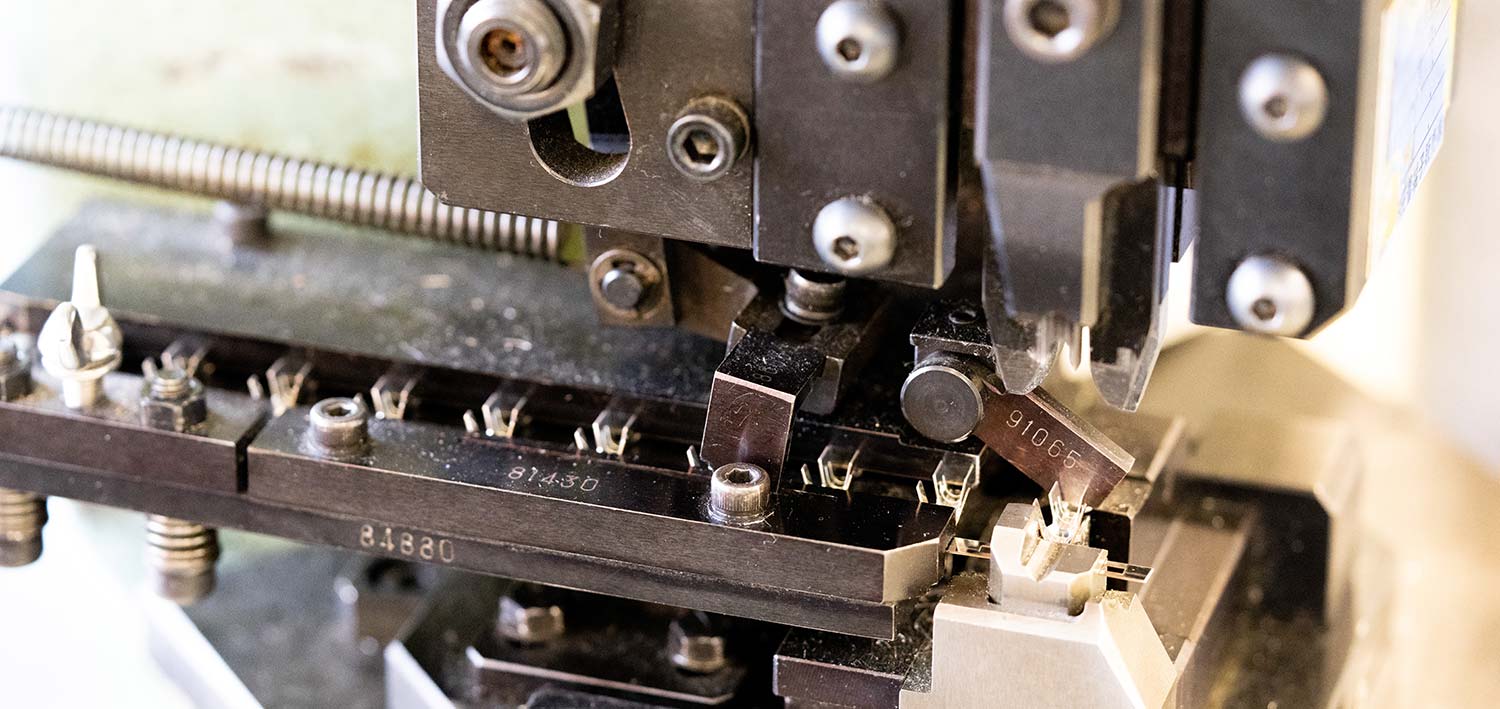

Press Machine

A mold is attached to the press machine, a material such as metal (work material) is sandwiched between the molds, and the material is pressed against the mold surface by vertical movement with a strong force to form the same shape as the mold.

Automatic Lathe

A lathe that can automatically feed blades. NC lathes are controlled by a computer, and those that do not use a computer but operate automatically fall into this category.

Centerless Grinding Machine

A grinding device used for finishing processed parts, which enables high-precision surface processing even with unstable shapes.

Our Cooperative Partners

| Product・Service | URL | Product Catalog | |

|---|---|---|---|

| ABBA LINEAR TECH CO.,LTD. | LINEAR MOTION GUIDE | www.abbalinear.com | – |

| TOPTECH DIAMOND TOOLS CO.,LTD. | SPECIAL TOOL | www.toptechdiamond.com | – |

| ANCA MANUFACTURING CO.,LTD. | ANCA CNC TOOL GRINDER | www.machines.anca.com | Download Catalog |

| SHANGHAI NAGOYA PRECISION TOOLS CO.,LTD. | GIVEAL CNC TOOL GRINDER | www.snstc.com | Download Catalog |

| SHANGHAI NAGOYA PRECISION TOOLS CO.,LTD. | SPECIAL TOOL | www.snstc.com | – |

| IKURASEIKI CO.,LTD. | BARTOP | www.ikura.com | Download Catalog |

| SUZUKI PRECISION CO.,LTD. | IB・SPINDLE | www.precion.co.jp | Download Catalog |